So, I had put off building a 44 because I already have so many blues in that wavelength and was hoping that a 10W diode would appear. Had one last MX900 with sink and enough $ in my paypal to cover the cost so I gave in as I also haven't seen or heard talk of any hotter diodes yet. Here's the 7W SXD-V3 4.5A build:

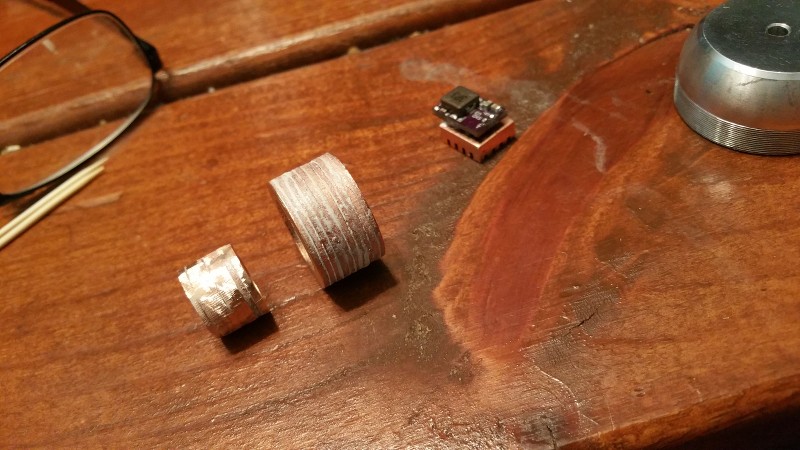

Started out I have a screw together sink as in the type where the diode sits into a groove of the front hald and then the back half screws down against the back side of the diode for cooling. Like a previous build I had decided because of how much room there is in the MX900 and the size of the sink to add some extra sink material with whatever I could come with that I had on hand. This resulted in a bunch of copper washers being thermal epoxied together under pressure and then using thermal epoxy again to the sink with pressure to make good contact with it. You can also see the SXD-V3 driver has a nice thick copper sink on it also:

![]()

![]()

![]()

![]()

General pic of the parts and then with the host changed to blue accents with blue electrical tape found at Harbor Freight in a 5 roll pack on clearance:

[IMG]http://imagizer.imageshack.us/v2/800x600q90/923/kc7gAk.jpg[/IMG

![]() ]

]

I also found a coupling that I cut down that created another outer ring around the washers and added that too:

![]()

What I'm showing here is a large copper fender washer and another stack of 3 more copper washers that I am going to add after I install the driver. I was doing parts of the build while awaiting the diodes arrival:

![]()

Now there is a reason why I have that fender washer. On all the screw down back half sinks I have seen the front of the diode sits into a shallow groove for the front section and there's a significant portion that ends up sticking up. When you screw down the back half of the sink so that it presses up against the back half of the diode you end up with an air gap all the way between the 2 sink halves. What I did was take an 8mm thick washer and basically sand it down to 4mm so that it is just a teeny tiny bit lower than the diode so that when I use thermal epoxy on both sides of the washer the gap will be covered and there will be better overall heat transfer between both sides of the sink:

![]()

![]()

I used MX4 carbon based thermal grease just in case there was any chance of it getting on the pins of the diode:

![]()

![]()

![]()

![]()

Diode arrived so it's wired up and ready to be installed:

![]()

All I'm really showing is that I used the non-conductive MX-4 on the back side of the diode also. This diode is harvested and the back side isn't perfectly flat and that's another reason for the thermal grease:

![]()

![]()

I was going to use those King Kong cells but my new 26650 25/50A cells arrived so I'm going with those instead. The sink halves are locked down very tight to each other with large wrenches:

![]()

Driver wired:

![]()

Not sure how I missed a picture of it but the drivers copper sink is just slightly longer than the driver on the half facing the diode on purpose so I could thermal epoxy it to the inner set of copper washers. I then epoxied the final 3 set of larger washers for the most sinking and wired it to the host:

![]()

![]()

Completed laser pics:

![]()

![]()

![]()

Started out I have a screw together sink as in the type where the diode sits into a groove of the front hald and then the back half screws down against the back side of the diode for cooling. Like a previous build I had decided because of how much room there is in the MX900 and the size of the sink to add some extra sink material with whatever I could come with that I had on hand. This resulted in a bunch of copper washers being thermal epoxied together under pressure and then using thermal epoxy again to the sink with pressure to make good contact with it. You can also see the SXD-V3 driver has a nice thick copper sink on it also:

General pic of the parts and then with the host changed to blue accents with blue electrical tape found at Harbor Freight in a 5 roll pack on clearance:

[IMG]http://imagizer.imageshack.us/v2/800x600q90/923/kc7gAk.jpg[/IMG

]

]I also found a coupling that I cut down that created another outer ring around the washers and added that too:

What I'm showing here is a large copper fender washer and another stack of 3 more copper washers that I am going to add after I install the driver. I was doing parts of the build while awaiting the diodes arrival:

Now there is a reason why I have that fender washer. On all the screw down back half sinks I have seen the front of the diode sits into a shallow groove for the front section and there's a significant portion that ends up sticking up. When you screw down the back half of the sink so that it presses up against the back half of the diode you end up with an air gap all the way between the 2 sink halves. What I did was take an 8mm thick washer and basically sand it down to 4mm so that it is just a teeny tiny bit lower than the diode so that when I use thermal epoxy on both sides of the washer the gap will be covered and there will be better overall heat transfer between both sides of the sink:

I used MX4 carbon based thermal grease just in case there was any chance of it getting on the pins of the diode:

Diode arrived so it's wired up and ready to be installed:

All I'm really showing is that I used the non-conductive MX-4 on the back side of the diode also. This diode is harvested and the back side isn't perfectly flat and that's another reason for the thermal grease:

I was going to use those King Kong cells but my new 26650 25/50A cells arrived so I'm going with those instead. The sink halves are locked down very tight to each other with large wrenches:

Driver wired:

Not sure how I missed a picture of it but the drivers copper sink is just slightly longer than the driver on the half facing the diode on purpose so I could thermal epoxy it to the inner set of copper washers. I then epoxied the final 3 set of larger washers for the most sinking and wired it to the host:

Completed laser pics: